Q&A – Knaus Tabbert: Navigating sustainable RVs

As decarbonising the transport sector continues to be a high priority for the European community, we turn our attention to what can be considered a subsector of electric vehicles: the recreational vehicle (RV) market. With a strong focus on sustainability and innovation, Knaus Tabbert is navigating the challenges of decarbonisation and leading the way in integrating electric solutions into its product offerings.

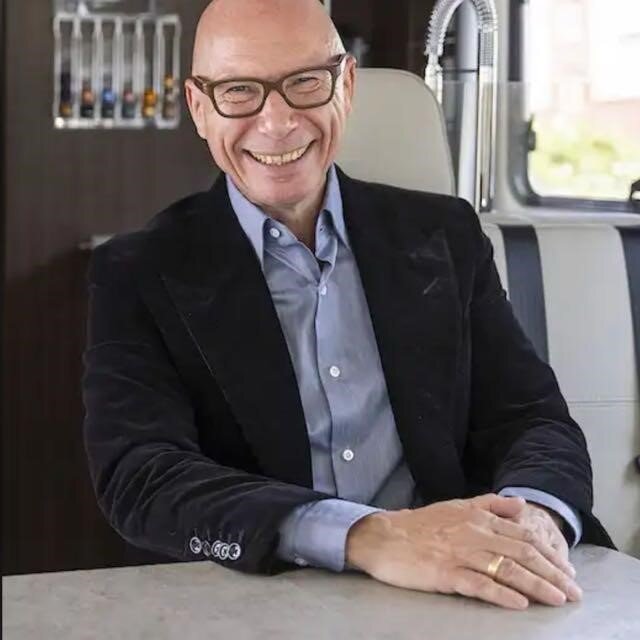

inspiratia sat down with Wolfgang Speck, CEO of Knaus Tabbert, to discuss the new RV market. In this interview, we delve into the company's market position, strategies, and the future of electric RVs as Knaus Tabbert adapts to the shifting landscape of customer expectations and technological advancements.

Could you provide an overview of Knaus Tabbert and its market position within Europe?

We are an RV manufacturer based in Lower Bavaria, Germany. In 2023, we achieved sales close to €1.5 billion (£1.28bn $1.65bn). Formed in 2013, Knaus Tabbert primarily served the European market. The total fleet size in Europe is around 5.4 million vehicles, with Germany holding the largest share at 1.2 million, followed by France with 1.1 million and the UK with roughly 800,000 vehicles. Our company is a significant player in this market, with a strong dealer network of around 500 independent dealers across Europe, most of which are family-owned businesses. We generate about two-thirds of our sales in Germany and 95% within Europe.

Additionally, we have established connections in South Korea and have recently started exploring the Malaysian market. We offer motorhomes and campervans, with motorhomes being the motorised vehicles. Our product range caters to a variety of customer needs within the RV market.

What is Knaus Tabbert's approach to sustainability and decarbonisation in the RV market?

Since 2013, the market has evolved. Looking back, the RV industry, which started in the 60s and 70s, was heavily dependent on passenger cars to tow caravans. Over the past decade, our product itself has become almost emission-free, apart from the gas installations we still use. When it comes to decarbonisation, we focus firstly on our production process. We strive to produce caravans in an emission-free environment. We have four production sites, including one near the Czech border and another in Hungary. Our site in Jandelsbrunn boasts the largest rooftop solar panel assembly in the region, producing 750kW peak.

Regarding the materials we use, our products predominantly feature pure wood, which is easy to recycle. We buy chassis from manufacturers like Fiat, Volkswagen, and Mercedes, which means we are somewhat dependent on their production strategies. While we buy the RVs from Original Equipment Manufacturers (OEM), which are diesel-based, we modify them for energy-efficient purposes. In our factories, we have large shops where we produce furniture from wooden plates for our RVs, such as kitchens, storage rooms, and toilet rooms. We utilise all the leftover material from production for heating, especially during winter months. This approach helps us maintain a gas-free environment. We also use photovoltaic systems, which significantly improve our CO2 footprint compared to other industries.

Studies show that using caravans or motorhomes for vacations results in much lower CO2 emissions compared to options like cruise ships, flights, or staying in large hotels. Our customers typically use their RVs for about 4,000km a year, which is relatively low compared to the annual mileage of passenger cars. This makes RV holidays one of the most environmentally friendly vacation choices.

Are you developing electric or hybrid RVs to reduce emissions further?

Yes, we are. We have started developing products that fit electric vehicles (EVs). For instance, we have a fully electric Fiat Ducato with our own electric powertrain system. This vehicle has a range extender and a small combustion engine that generates electric energy when the battery level is low. This setup allows the vehicle to be driven fully electric in cities and switch to the range extender for longer trips. This innovation ensures that the motorhome is always electric-driven, with the range extender providing additional energy when needed.

As for the production of EV batteries, we do not produce them ourselves but purchase them from local suppliers or dealers who offer complete solutions. Some of these batteries come from China. We work with major companies like Iron Hill in Germany, although their component sources can vary. We ensure our suppliers adhere to ethical standards, including avoiding child labour. Battery technology is advancing rapidly, and I believe we will see significant improvements in storage power soon, similar to the rapid progress seen in artificial intelligence. This will help us meet future energy needs sustainably.

How has the market responded to electric RVs, and what challenges exist for wider adoption?

While we have made progress, the demand for electric motorhomes is still limited. Many of our customers prefer diesel engines due to their efficiency and the existing infrastructure, especially in remote areas like Scandinavia. However, we are prepared to meet future demand and continue developing our own solutions to stay ahead. We will continue to enhance our production processes and develop more sustainable products. We are also waiting for OEMs to bring advanced electric solutions to the market, which we will integrate into our RVs. Our goal is to remain a leader in the RV industry by offering innovative and environmentally friendly products.

The current lack of charging infrastructure can be a limiting factor for the use of electric caravans, especially for long-distance travel. However, most caravan users drive within a manageable distance, allowing for overnight charging at their destination. As electric motorhomes become more common, this issue may become more pronounced, but I anticipate significant improvements in charging infrastructure by 2035. For now, diesel engines and gas systems remain popular due to their reliability in regions with limited infrastructure. While expanding charging networks in remote areas may be challenging, innovative solutions could emerge.

In terms of demand, customers under 40 often prefer caravans without gas installations, especially if they have electric passenger cars. They want purely electric-powered caravans, which we already offer. For motorhomes, the challenges are different. Customers need a range of 600-700km and are not willing to stop frequently to recharge. They also need reliable heating systems, often diesel-powered, especially when travelling in areas with limited infrastructure like Scandinavia. Despite this, we are working on future solutions and collaborating with OEMs. However, we also need to be realistic about the current market and customer demands. Our goal is to balance customer needs, legal requirements, and our sustainability goals.

Looking ahead, how do you plan to tackle these challenges?

Over the next ten years, we expect to see more solutions aligning with the decarbonisation strategy in our portfolio. We need to educate our customers, as developing products that nobody wants to buy won't solve the problem. We need to balance customer demands and legal requirements. Mercedes recently announced a shift to a 100% EV strategy but will still produce a combustion engine S-class model in three years. This reality shows the complexity of the transition. We need to take a step-by-step approach, considering customer acceptance and the broader industry context. The supply chains are long and complex, impacting our ability to produce and innovate effectively. But we are hopeful.