Building up Hydrogen Carriers – Hydrogenious LOHC Q&A

EU

RenewablesQ&AThe future green hydrogen economy will require a slew of innovative technological solutions to bring together producers and users. inspiratia spoke to Dr Andreas Lehmann, CSO of Hydrogenious LOHC, one of the businesses that are taking on the challenge of transporting hydrogen over long distances – a necessity if the hydrogen market is ever going to reach its full potential

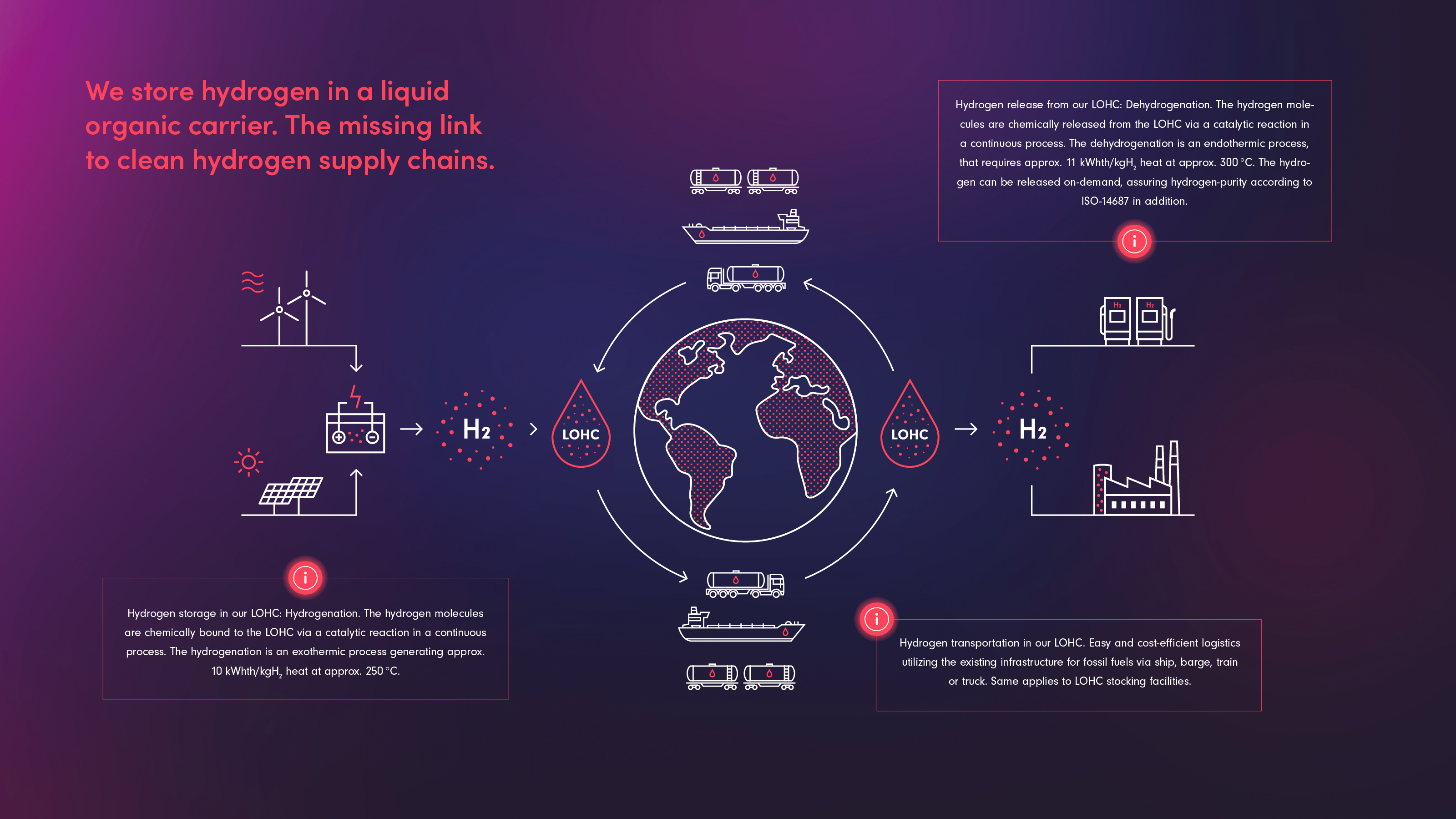

Hydrogenous LOHC (Liquid Organic Hydrogen Carrier) has been leading the way on creating chemical hydrogen carriers, and developing transport solutions for land and sea. Its proprietary technology allows the company to densely 'charge' a chemical solution with hydrogen molecules and then release these molecules at the destination.

inspiratia insights:

- Reliable, efficient, and safe carriers will be needed to connect hydrogen producers with consumers.

- First movers like Hydrogenious are already deploying their technology at smaller scales, with solid plans for expanding their operations as the hydrogen market opens up.

- Building partnerships across the whole value chain is key to the role of the future middlemen of the hydrogen market.

- Clear and decisive movement from regulators is needed to unlock the future potential of a hydrogen market.

Can you describe the decision-making process that led to settle on your chosen LOHC?

We have researched different carrier materials as LOHC for many years - among others carbazole, toluene and dibenzyltoluene. We have clearly identified for benzyl toluene as superior, because it is very safe, robust, and has a lot of compelling properties as a LOHC:

It's hardly flammable with flash point 130 °C, non-explosive, even when loaded with hydrogen and it can be handled under ambient temperatures and pressure during storage and transport – the hazard potential even smaller than for diesel. Also, there is no self-discharge over time. It has a competitive volumetric storage density of 54 kg hydrogen per cubic meter of LOHC and the carrier material is commercially available in larger quantities and reusable hundreds of times. Last but not least, benzyl toluene is very stable within the process, therefore enabling a high number of cycles, high hydrogen purity and long catalyst lifetime.

How far is the technology from achieving full commercialisation?

We do have several realised projects, while the project with H2Mobility Germany – a Hydrogen Refuelling Station in Erlangen – is already commercial: Here, we supply hydrogen via our LOHC in a small-scale project to a hydrogen refuelling station. But what we are mainly focussing on as a company right now are industrial sized projects at larger scales. We are working on the first commercial-size plant with five tonnes of hydrogen per day to be stored using the LOHC technology in Chempark Dormagen, Germany. Start of construction for this plant is planned for 2023.

As part of the Northern Green Crane project, Hydrogenious will build a 24-tonnes-per-day hydrogenation plant in Sweden to store green hydrogen in LOHC. From Sweden, the LOHC will be transported by ship to Rotterdam in the Netherlands and by barge via the river Ems to Lingen in Germany, where the green hydrogen is released for industrial off-takers. We already work on even larger-scale projects with LOHC with volumes of 100, 200 and even 500 tonnes of hydrogen to be stored and released per day for imports and exports.

© Hydrogenious LOHC Technologies

Which of your current projects is furthest along in development, and when can full scale operation start?

We have several smaller facilities running in the "market" since 2016. Now, the next big milestone will be the storage plant in Chempark Dormagen which is estimated to be on stream in 2025. This will then be the largest LOHC plant in the world, by the way. For Northern Green Crane, hydrogen imports via LOHC are planned to be realized from 2026.

What business model will Hydrogenous ultimately pursue in the future hydrogen transport market?

Starting from our "core" Hydrogenious LOHC Technologies is at heart a technology company, but as a growing group, we pursue business models and develop solutions for long-distance hydrogen supply chains worldwide, based on our unique LOHC technology. Our goal is to connect hydrogen producers and consumers in a superior safe, easy, and of course cost-efficient way, independent of location and complexity of routes.

We provide LOHC plants that enable large-scale storage and release of hydrogen, which we offer on a turnkey level in a joint venture with our EPC partner Bilfinger. We also act as a plant operator and offer corresponding services for other owners and/or operators.

Moreover, our business model includes LOHC logistics, and we are on the verge of establishing a separate JV company for this purpose as well, together with an established infrastructure professional for handling chemicals. Hydrogen trading will be also conceivable for us in the future and while further developing our innovative technology, we are also open to licensing models – we already do have various licensees, e.g., Schaeffler, as announced in January 2022.

Much of the market discourse around the marine transport for hydrogen is concerned with ammonia. Is there room for both LOHC and ammonia to serve as hydrogen carriers, or will one ultimately win out over the other?

Different carriers each have their own advantages and disadvantages. In our view there is no such thing as a "perfect" solution that fits all when it comes to hydrogen transport and there is room for both technologies. After all, also today there are different energy carriers that coexist. However, our LOHC is very versatile and furthermore, compared to almost all alternatives, very safe to handle and therefore has the best chance of becoming a universal energy carrier of choice.

What key partnerships has the business built in the emerging hydrogen sector?

As mentioned before, we align with experts in their fields to establish superior supply chain business models. To ramp-up the hydrogen industry, we are currently developing the whole hydrogen, and thus LOHC supply chain in joint projects with companies that invest with us to push innovation further and to leverage advantages for every partner. That means, we have partners on the renewable energy/hydrogen production side, on the transportation and logistics side, and on the primarily industrial hydrogen off-taking side.

A good example is our cooperation with the Abu Dhabi National Oil Company (ADNOC), Jera Americas and Uniper, where we are exploring a large-volume hydrogen supply chain from UAE to Europe, which includes LOHC plant systems and the associated infrastructures with volumes of approx. 10,000 up to 180,000 tonnes of hydrogen per year. Or the mentioned Northern Green Crane project, and our joint work within H2A with the port of Amsterdam and Evos to develop large-scale hydrogen import facilities in the port of Amsterdam.

With which of hydrogen's many potential applications does LOHC transport best align?

Ports are very relevant as import hubs for Hydrogen and derivatives, hence also for LOHC. The potential to reuse existing infrastructure for transport, handling and storage is a tremendous factor. In combination with the ease of handling LOHC offers perfect flexibility to all kinds of supply chains – close to ports or further in the hinterland.

As the need to decarbonise for industrial users is very high, this is the market segment we are focussing now. But the hydrogen released from LOHC easily achieves fuel cell purity (see our project with H2 Mobility Germany supplying a hydrogen refilling station via LOHC), which means that there is no difference regarding the technical aspects of industrial and mobility applications... it's only the willingness and necessity of now realising large-volume projects which we see in the industry like refineries, glass industry, steel etc.

How does Hydrogenious benefit from the hydrogen policies of both the EU and national governments?

First and foremost, Hydrogenious benefits from a sound regulatory framework like incentives and requirements for hydrogen projects. This also means technology-agnostic hydrogen policies on EU and national level.

Like many other companies, we advocate for this approach towards all stakeholders. If we want to reach the hydrogen import goals, which the European Commission set for 2030, we need policies to be formulated in a way that is open to the best solutions, i.e., technology agnostic.

For ramping-up the hydrogen industry in the European Union, the EU as well as national and state governments invest and fund various projects and Hydrogenious LOHC Technologies also benefits from such funds, for example the EU innovation fund or Horizon Europe. Also, two of our projects, Green Hydrogen@Blue Danube and Northern Green Crane are currently in German IPCEI Hydrogen notification process.

Hydrogenious would also benefit from clear legislations on the import of hydrogen from third countries to the European Union. Europe will need for the decarbonized energy transition the possibility of importing green hydrogen. Therefore, the regulation should not artificially increase the costs for green hydrogen.

What is the main obstacle that Hydrogenious needs to navigate in the coming months? And how are you confronting it?

In general, hydrogen shows significant differences from natural gas especially regarding its production, transportation, and storage. It is therefore important to ensure proper regulation of technological diversity with avoidance of any possible barriers.

We as a company work on the proof that LOHC technology works in multi-ton hydrogen-per-day magnitude and that it can be scaled even further. That is why we are pushing ahead with development independently of regulation through industrial-scale projects like in Chempark Dormagen, Germany.

The hydrogen industry will only evolve if the rules of the game are clear. It is of utmost importance that the EU now moves forward and creates a regulatory framework that ensures clarity while assuring technological neutrality.

It is important to drive the regulatory framework and keep it as simple as possible. We are constantly in touch with various stakeholders on political, institutional, industrial, and social levels to create awareness for these issues.